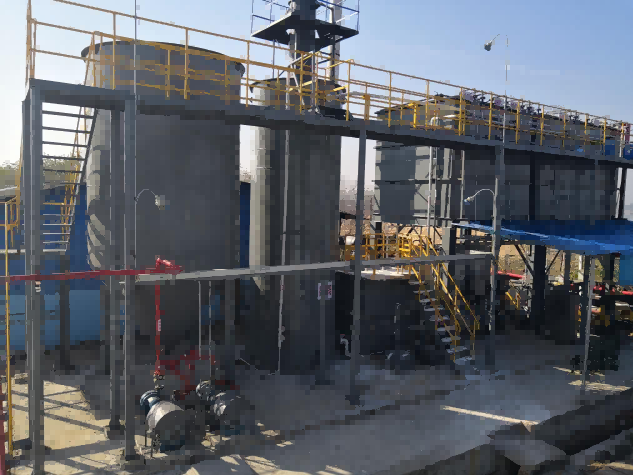

Product features: MVR is a steam mechanical recompression technology that reuses the energy of the secondary steam generated by itself, thereby reducing the demand for external energy. The working process of the evaporator is to compress the low-temperature steam through the compressor, increase the temperature and pressure, increase the enthalpy, and then enter the heat exchanger for condensation to fully utilize the latent heat of the steam. Except for start-up, there is no need to add steam during the entire evaporation process. This technology is widely used in fields such as chemical engineering, food, papermaking, medicine, seawater desalination, and sewage treatment.

Technical advantages:

☆ Recycle the latent heat of secondary steam, completely avoiding the use of fresh steam, greatly reducing energy consumption

☆ Completely abandoning the cooling tower and eliminating the circulating cooling water, greatly reducing operating costs

☆ Compact structure, smooth operation, high degree of automation

☆ For thermosensitive materials, a vacuum pump can be used in conjunction to achieve low temperature evaporation under a vacuum close to absolute pressure, with a minimum evaporation rate of 30 degrees Celsius