Product Center

-

Biotechnology Series Products

-

Wastewater Physicochemical Technology Series Produ

-

Waste Gas Treatment Products

-

Solid Waste Treatment Products

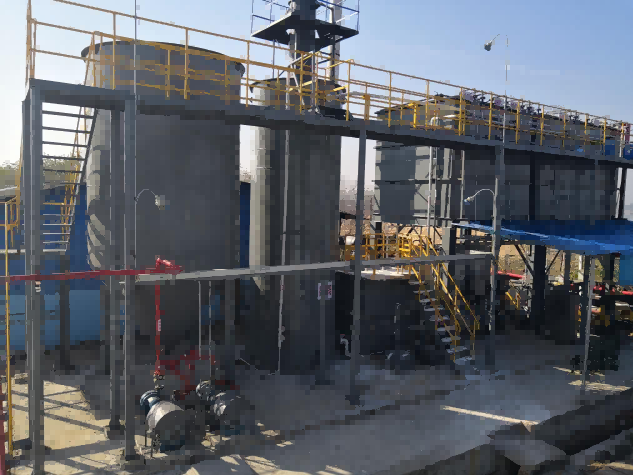

Wastewater Physicochemical Technology Series Produ

-

HEM-BAF Aerated Biological Filter Reactor

HEM-BAF adopts a reasonable filling method by combining two or more types of filter materials, such as ceramic particles and zeolite, in a certain proportion, and filling them into the aerated biological filter tank. It is inoculated with HEM high-efficiency biological bacteria, and after cultivation and domestication, it can achieve deep treatment of wastewater, making the organic matter or ammonia nitrogen in the wastewater meet the discharge requirements. -

HEM-CBR Continuous Flow Aerobic Reactor

HEM-CBR is a continuous flow aerobic biological reaction process characterized by the addition of HEM efficient composite aerobic bacteria and carriers in the aerobic tank. -

HEM-IBR fixed bed bioreactor

HEM-IBR is a fixed bed bioreactor that combines HEM efficient bacterial strains and biological fillers to develop an efficient wastewater treatment process. The biological filler is fixed in the biochemical reaction tank, and the wastewater flows through each biochemical reaction tank in a push flow manner. Different pollutants in the wastewater come into full contact with efficient bacteria attached to the filler, and degrade in different intervals along the longitudinal direction of the reaction tank. -

HEM-ABR high-efficiency biological strain anaerobic reactor

HEM-ABR is a new anaerobic technology that combines microbial screening technology with anaerobic reactor engineering technology. -

Steam Mechanical Recompression Technology (MVR)

MVR is a steam mechanical recompression technology that reuses the energy of the secondary steam generated by itself, thereby reducing the demand for external energy. The working process of the evaporator is to compress the low-temperature steam through the compressor, increase the temperature and pressure, increase the enthalpy, and then enter the heat exchanger for condensation to fully utilize the latent heat of the steam. Except for start-up, there is no need to add steam during the entire evaporation process. This technology is widely used in fields such as chemical engineering, food, papermaking, medicine, seawater desalination, and sewage treatment. -

Heterogeneous catalytic oxidation technology

The principle of heterogeneous catalytic oxidation technology is the same as that of Fenton oxidation. It reacts with organic pollution factors in wastewater through strong hydrogenation agents and supported catalysts, achieving ring opening and bond breaking of organic compounds, reducing COD in wastewater, improving biodegradability of wastewater, and creating conditions for subsequent biochemical treatment. -

Catalytic Microelectrolysis Technology

The catalytic micro electrolysis process is based on the conventional micro electrolysis process. By improving the structure of the micro electrolysis reactor, optimizing the types of micro electrolysis fillers, filling methods, and process control, it effectively overcomes the shortcomings of traditional micro electrolysis processes such as filler passivation, hardening, channeling, and large slag content. It fully utilizes the various functions of micro electrolysis, such as flocculation, adsorption, bridging, sweeping, co precipitation, electrodeposition, and electrochemical reduction, Complete the reduction of wastewater toxicity and improvement of biodegradability.